Antwort Is 5 Sigma better than 6 Sigma? Weitere Antworten – What is the difference between 5 and 6 Sigma

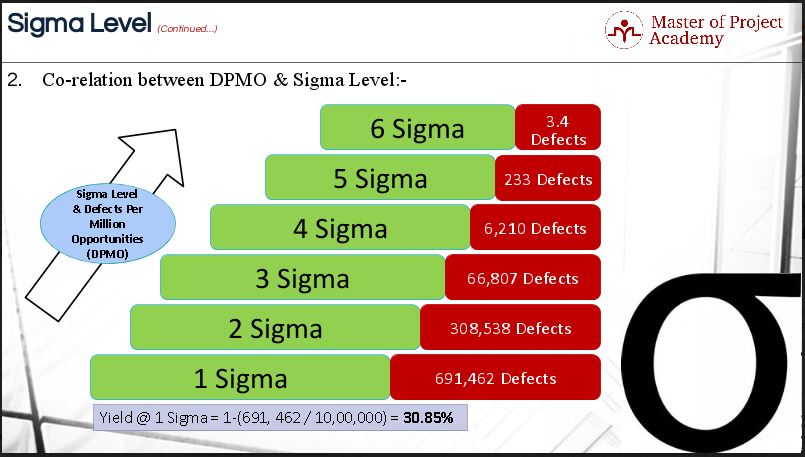

5S focuses on eliminating waste and inefficiencies in the workplace. This methodology can be applied to every department and action that takes place. On the other hand, Six Sigma is a process improvement strategy that eliminates defects by implementing standard processes, identifying problem areas, and more.The more number of standard deviations between process average and acceptable process limits fits, the less likely that the process performs beyond the acceptable process limits, and it causes a defect. This is the reason why a 6σ (Six Sigma) process performs better than 1σ, 2σ, 3σ, 4σ, 5σ processes.Lean Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

Is higher sigma better : This measures the number of standard deviations from the mean performance of a procedure or product. The higher the Sigma Level, the better the performance.

How rare is 5 sigma

For other results, like the Higgs boson discovery, a five-sigma significance is the 0.00003% likelihood of a statistical fluctuation, as scientists look for data that exceeds the five-sigma value on one half of the normal distribution graph.

How unlikely is 5 sigma : In particle physics five-sigma, is the accepted level of significance required to declare a discovery. This corresponds to a probability of 0.00002% which might seem to many to be rather extreme. In fact, for many scientists a two-sigma result would be deemed adequate in order to publicise their results.

Lack of resources.

Getting sufficient numbers of “belts” trained at whatever levels is a major investment, not only in actual cash for the training, but in terms of time and adding extra work to busy managers' lives. Is it seen as too complicated In some quarters, Six Sigma is regarded as too complicated.

Despite lean six sigma's long track record of delivering transformational results, in recent years, the strategy has been overlooked. Sometimes conflated with more austere strategies such as “just in time manufacturing”, in recent years lean six sigma has fallen out of fashion, or at least seemed to.

What is difference between 5S and 6S

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.The idea of 5S in Six Sigma denotes a method of paying attention to and thinking in order to better organize and manage the workspace, particularly by getting rid of 8 waste as explained by the Lean Manufacturing system.Three Sigma allows for a greater number of defects per million, whereas Six Sigma requires near-perfect accuracy. This means that many companies consider anything below Six Sigma to be unacceptable. Three Sigma's rate of accuracy is more common among manufacturing companies that are still new in the industry.

:max_bytes(150000):strip_icc()/six-sigma-e6a4f14ddb5b4b928a4945739be3bd37.jpg)

Usually, a process with a Sigma Level of 6 or greater is usually considered as an excellent process.

What is a 5 sigma equal to : For other results, like the Higgs boson discovery, a five-sigma significance is the 0.00003% likelihood of a statistical fluctuation, as scientists look for data that exceeds the five-sigma value on one half of the normal distribution graph.

What is the IQ of sigma : For IQ tests, 1 sigma = 15 points. The 68-95-99.7 rule tells us that 68% of the population is between -1 and +1 sigma from the average; 95% is between -2 and +2 sigma from the average; and 99.7% is between -3 and +3 sigma from the average.

How accurate is the 5 sigma

In most cases, a five-sigma result is considered the gold standard for significance, corresponding to about a one-in-a-million chance that the findings are just a result of random variations; six sigma translates to one chance in a half-billion that the result is a random fluke.

The term "Six Sigma" refers to a statistical measure of how far a process deviates from perfection. A process that operates at six sigma has a failure rate of only 0.00034%, which means it produces virtually no defects.If you're asking, “Is Six Sigma still relevant,” the answer is: absolutely! Many of the most cutting-edge companies, such as Microsoft and Pfizer, still use Six Sigma and Lean Six Sigma to enhance their processes, reduce errors, and optimize performance.

Why is 6S better than 5S : 6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.